Hat Style Harmonic Solutions

Precision Motion.

Precision Motion.

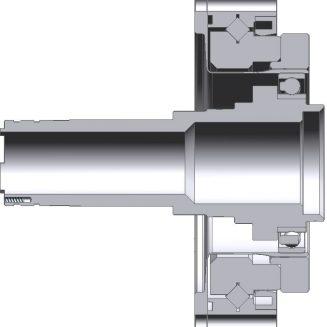

Cone Drive’s harmonic gearing (also known as strain wave gearing) is an in-line motion control solution consisting of three main components: a wave generator, flexspline, and a circular spline. Cone Drive is one of the few harmonic solution developers in the world. Our team of engineers is ready to design, spec, produce, and test a harmonic gearing solution for your specific application.

Key Features

- Sizes: 14, 17, 20, 25, 32

- Configuration: gear set or gear head (multiple gear head options)

- Interface: metric

- Continuous Output Torque: Up to 196 Nm

- Peak Output Torque: Up to 900 Nm

- Gear Ratios: 50:1 to 160:1; ratio offerings are size dependent

- Input Options: Oldham coupling, servo motor interface, stepper motor interface

Harmonic gearing is low to zero backlash by design. It provides high transmission accuracy and can support a high ratio reduction in a single stage with lower inertia. The highly accurate, torque dense design makes harmonic gearing the perfect solution for robotic and other positioning control applications.

Download Overview

Download Overview